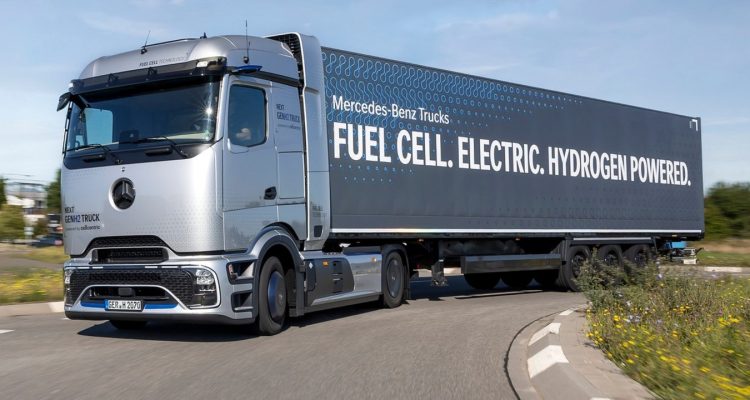

Daimler Truck has revealed the Mercedes-Benz NextGenH2 Truck, marking a major milestone in the manufacturer’s development of hydrogen-powered heavy goods vehicles. Following an extensive development and testing programme with first-generation fuel cell truck prototypes, the new model represents the next technological step towards sustainable long-haul transport.

The NextGenH2 Truck will enter a small-series production run at the Mercedes-Benz plant in Wörth, where 100 semi-trailer tractors will be built. These vehicles are scheduled to be deployed with selected customers from the end of 2026, operating in real-world long-haul applications.

Achim Puchert, CEO of Mercedes-Benz Trucks, said: “In addition to battery-electric solutions, hydrogen-based drives are crucial for the sustainable transformation of our industry. With the NextGenH2 Truck, we are taking the next technological step in fuel cell trucks. Together with our customers, we aim to introduce the small series with high range and near production-ready technology into daily transport operations from the end of 2026.”

Liquid hydrogen delivers ranges beyond 1,000 kilometres

In developing hydrogen-based drivetrains, Daimler Truck continues to focus on liquid hydrogen rather than gaseous hydrogen. Stored at -253°C, liquid hydrogen offers a significantly higher energy density, enabling longer ranges, improved efficiency and performance comparable with today’s diesel trucks.

The Mercedes-Benz NextGenH2 Truck builds on the strengths of the earlier GenH2 model, with increased liquid hydrogen storage capacity. The two onboard tanks can now hold up to 85 kg of liquid hydrogen and are connected to allow refuelling from either side of the vehicle.

Using the sLH2 refuelling standard developed jointly by Daimler Truck and Linde, the truck can be refuelled in approximately 10 to 15 minutes. The process is designed to be as safe, fast and straightforward as conventional diesel refuelling, supporting the operational demands of long-distance haulage.

Liquid hydrogen also reduces logistical complexity and offers cost and weight advantages over high-pressure gaseous systems. These benefits support higher payloads, enabling hydrogen trucks to operate on par with diesel vehicles. Daimler Truck previously demonstrated this capability during the #HydrogenRecordRun in 2023, when a Mercedes-Benz GenH2 Truck covered 1,047 km on a single tank fill at a gross combined weight of around 40 tonnes.

Proven fuel cell technology at the core

At the heart of the NextGenH2 Truck is the BZA150 fuel cell developed by cellcentric, the joint venture between Daimler Truck and Volvo Group. The vehicle uses a twin fuel cell system delivering a combined output of 300 kW, with two 150 kW units compactly integrated beneath the cab.

Years of intensive testing have demonstrated the reliability and efficiency of the hydrogen-powered drivetrain under real-world conditions. During early customer trials with the GenH2 Truck, hydrogen consumption averaged between 5.6 kg and 8 kg per 100 km, depending on operating conditions and gross vehicle weight, which ranged from 16 to 34 tonnes.

During operation, the fuel cell generates electricity through the reaction of hydrogen and oxygen. Together with a high-voltage buffer battery, this energy powers the electric motors integrated into the e-axle. The only emission produced is water vapour.

Series components bring a step change in maturity

A key advancement of the Mercedes-Benz NextGenH2 Truck is its use of proven series components from the manufacturer’s battery-electric trucks. This includes the latest generation integrated e-axle from the eActros 600, the aerodynamically optimised ProCabin, the Multimedia Cockpit Interactive 2, and the latest safety and driver assistance systems.

The ProCabin, already used on the Actros L and eActros 600, appears for the first time on a fuel cell truck. Compared with the previous cab, it delivers a nine per cent improvement in aerodynamic efficiency, contributing to improved range and energy consumption.

The driving experience mirrors that of the eActros 600, with instant torque delivery, smooth power response and low noise levels. Even under demanding conditions such as steep gradients or heavy payloads, the truck delivers up to 340 kW in Economy mode and up to 370 kW in Power mode.

Energy storage is provided by a Daimler Truck-developed high-voltage lithium-iron-phosphate battery with an installed capacity of 101 kWh. Acting as a buffer for the fuel cell, it also stores energy recovered during braking and downhill driving. The 4-speed electric drive axle, including two reverse gears, ensures efficient power delivery across all driving situations.

Improved usability informed by customer trials

Feedback from early GenH2 customer trials has directly influenced the design of the NextGenH2 Truck. A redesigned and more compact Tech Tower behind the cab has enabled the wheelbase to be shortened by 150 mm to 4,000 mm, increasing flexibility for different trailer combinations while remaining within EU length regulations.

The Tech Tower also incorporates a new boil-off management system that meets all regulatory requirements for handling hydrogen, including safe parking in enclosed spaces. An integrated cooling system maintains stable operating conditions in high ambient temperatures and challenging terrain.

New hydrogen sensors further enhance safety, allowing overnight stays in the cab’s two standard beds. This improves comfort and flexibility for long-haul drivers on multi-day operations. In addition, redesigned side panels with integrated crash elements offer improved protection for the liquid hydrogen tanks while also improving aerodynamics and accessibility.

Testing and funding support future deployment

Prototypes of the Mercedes-Benz NextGenH2 Truck have undergone extensive testing under extreme conditions, including winter and summer trials in the Swiss Alps. Insights from these tests are being fed directly into ongoing development ahead of customer deployment.

The development, production and real-world operation of the NextGenH2 Trucks from the end of 2026 is supported by funding of €226 million from the German Federal Ministry of Transport and the federal states of Rhineland-Palatinate and Baden-Württemberg. Daimler Truck is targeting series production of fuel cell trucks in the early 2030s