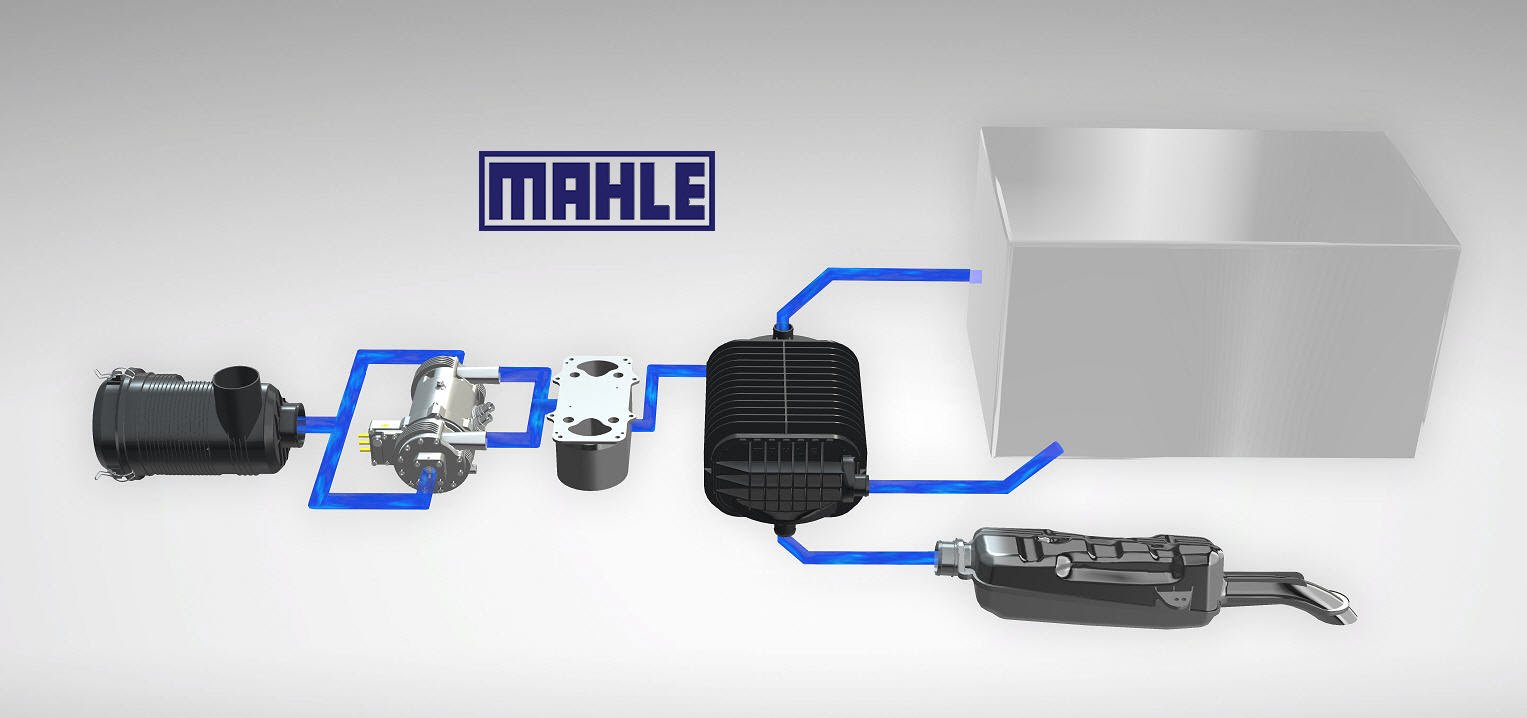

The first demonstrator vehicle for a novel new hydrogen fuel cell technology is in development by MAHLE Powertrain. As integration partner to hydrogen fuel cell specialist, Bramble Energy, MAHLE Powertrain is helping to optimise the integration of the company’s Printed Circuit Board Fuel Cell (PCBFC™) technology within the powertrain of a Renault Kangoo ZE. The vehicle, which will be unveiled in 2021, will showcase the reduced-cost, high performance potential of high power density liquid cooled fuel cells.

“Hydrogen is certainly a viable option for the light commercial vehicle sector,” says Jonathan Hall, MAHLE Powertrain’s head of research & advanced engineering projects. “We are delighted to be working with Bramble Energy on such an exciting and timely project. The commercial vehicle sector is currently exploring alternative fuel options as several large fleet operators pledge to meet net-zero CO2 emission. PCBFCä technology provides a high power density solution that is perfectly suited to typical commercial vehicle duty cycles. In addition, we hope accelerated development of fuel cell technologies will have the knock-on effect of inspiring increased deployment of supporting infrastructure for areas where it is currently lacking.”

MAHLE Powertrain was chosen to support Bramble Energy on the integration project, which leverages high volume printed circuit board manufacturing techniques to reduce cost and ease of production scalability, due to its expertise in EV control systems, zero-emission vehicle systems integration and cooling system development.

MAHLE Powertrain was chosen to support Bramble Energy on the integration project, which leverages high volume printed circuit board manufacturing techniques to reduce cost and ease of production scalability, due to its expertise in EV control systems, zero-emission vehicle systems integration and cooling system development.

Utilisation of PCB technology enables Bramble Energy to offer a bespoke fuel cell capability and enhanced production flexibility, plus a robustness inherent in the printed circuit board manufacturing process. It also enables the company to strip-back fuel cell complexity and reduce weight, negating the need for separate sealing materials and lowering the number of components without negatively impacting build quality or performance.

“We’re excited to be working with MAHLE Powertrain on this integration project and to be so close to showcasing the benefits of our PCBFC™ technology in a liquid-cooled application,” says Dr Tom Mason, Bramble Energy CEO and CTO. “Delivery of this project will be a milestone moment for both Bramble Energy and net-zero CV powertrains and we cannot wait to demonstrate the tangible performance and cost benefits to the CV industry.”

Bramble Energy’s fuel cell solution has already been demonstrated for air cooled applications and will be launched – as the SD product range – in collaboration with BOC in the near future.